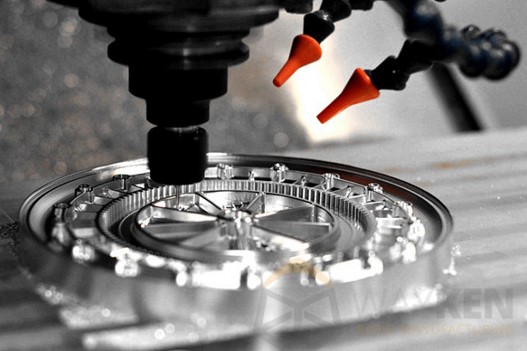

CNC Milling

Everlucky has 12 sets of four-axis and the others are three-axis CNC machines in the house, the tolerance we can meet is +/-0.01.

CNC Milling

What is a CNC Milling Machine and how does it work? How do CNC milling machines compare to CNC Lathes? When do you need such a CNC machine tool?

Focused on milling – the process of machining using rotating tools to gradually remove material from a workpiece – CNC milling machines are a mainstay for factories around the world. These machine tools make use of a variety of cutting tools along one or more axes to remove material from a workpiece through mechanical means.

CNC milling machines are often used in a variety of manufacturing industries: from industries like aerospace, shipping, automobiles, and oil drilling /pumping and refining, to medical, FMC manufacturing, and precision engineering sectors. Also called CNC Machining Centers, the more advanced CNC milling machines can operate along multiple-axis. These may be fitted with automatic tool changers, advanced machine coolant systems, pallet changers, and advanced software to improve the efficiency and accuracy of machining processes.

– CNC Milling: Use a multi-point rotating tool to remove material from the workpiece. Basic mills consist of a 3-axis system (X, Y, and Z), which is still one of the most popular and widely used machining processes. In 3-axis machining, the workpiece remains fixed, and the rotating tool cuts along the x, y, and z axes. Meanwhile, most newer mills can accommodate two additional axis, 4-axis CNC machining and 5-axis CNC machining have higher versatility, and they are often used in the production of high-precision parts.

Products

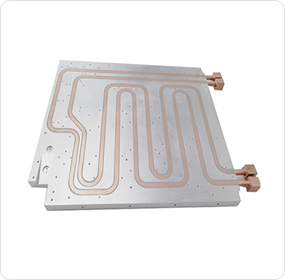

CNC precision milling machining part

for high-power equipment

Customized CNC precision

machining part