Friction Stir Welding

Friction Stir Welding

Friction stir welding (FSW) is a solid-state joining process that uses a non-consumable tool to join two facing workpieces without melting the workpiece material. Heat is generated by friction between the rotating tool and the workpiece material, which leads to a softened region near the FSW tool. While the tool is traversed along the joint line, it mechanically intermixes the two pieces of metal, and forges the hot and softened metal by the mechanical pressure, which is applied by the tool, much like joining clay, or dough. It is primarily used on wrought or extruded aluminum and particularly for structures which need very high weld strength. FSW is capable of joining aluminum alloys, copper alloys, titanium alloys, mild steel, stainless steel and magnesium alloys. More recently, it was successfully used in welding of polymers. In addition, joining of dissimilar metals, such as aluminum to magnesium alloys, has been recently achieved by FSW. Application of FSW can be found in modern shipbuilding, trains, and aerospace applications.

Principle of operation

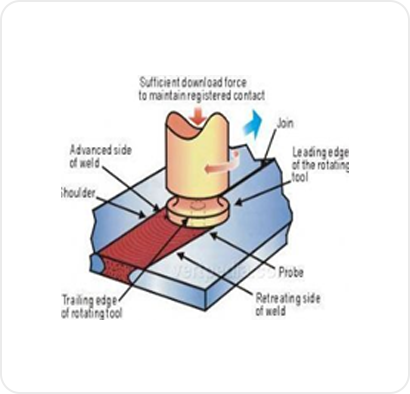

The FSW is performed with a rotating cylindrical tool which has profiled pin (also known a probe) having diameter smaller than the diameter of shoulder. During welding the tool is fed into a butt joint between two clamped workpieces, until the probe pierces into the workpiece and shoulder touches the surface of the workpieces. The probe is slightly shorter than the weld depth required, with the tool shoulder riding atop the work surface. After a short dwell time, the tool is moved forward along the joint line at the pre-set welding speed.

Frictional heat is generated between the wear-resistant tool and the work pieces. This heat, along with that generated by the mechanical mixing process and the adiabatic heat within the material, cause the stirred materials to soften without melting. As the tool is moved forward, a special profile on the probe forces plasticized material from the leading face to the rear, where the high forces assist in a forged consolidation of the eld.

This process of the tool traversing along the weld line in a plasticized tubular shaft of metal results in severe solid-state deformation involving dynamic recrystallization of the base material.

Advantages of friction stir welding

The advantages of friction stir welding arise from its unique weld where there is no use of consumables or shielding element techniques. This gives the following characteristics to the weld

- The finished weld is seamless and aesthetical

- It can weld otherwise un-weldable alloys like the Aluminum 2xxx and 7xxx range

- Fully automated process

- No form of flux or shielding agent required

- Low peak temperatures prevent shrinkage and porosity of the cracks.

- Limitations of friction stir welding

- Unlike other welding tools, the tool used in friction welding has to provide forging action to the workpieces besides heating them. So, the tool must withstand significant loads and should not produce excessive wear.

- This is one of the reasons why frictions stir welding is not used commonly on hard steel or metals. Also, a hole will be left behind by the profiled pin when it leaves the workpiece. Stir welding is mainly used to weld aluminum and it can weld nearly all types of aluminum, even the modern Al-Li alloys. The reason why it is restricted to aluminum is because aluminum welds can happen at relatively low peak temperatures.