Our services are cover Military, Medical, Auto,

Solar and Wind power, New-energy, Fiber Laser,

Electric and Telecom industries.

CNC Machining

Our machining service include CNC milling, CNC turning, Punching, Die casting, Plastic mold, Skiving, Epoxy bonding fin, Friction stir welding, Wire Electrical Discharge Machining (WEDM) processes. We can do one-stop solutions from design to manufacturing.

CNC Milling

Focused on milling – the process of machining using rotating tools to gradually remove material from a workpiece – CNC milling machines are a mainstay for factories around the world.

CNC Turning

We provide the best in CNC lathe machining and turning services. Equipped with highly skilled CNC programmers and machinists, as well as horizontal and vertical turning centers, we consistently exceed our clients’ precision, accuracy, and quality standards.

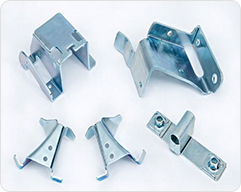

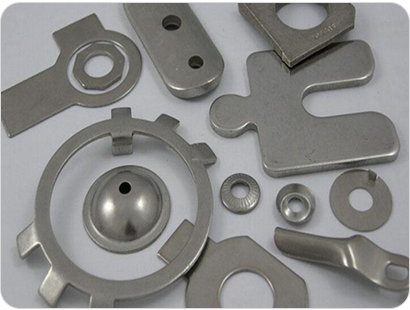

Stamping & Bending & Punching Process

Metal stamping is a cold-forming process that makes use of dies and stamping presses to transform sheet metal into different shapes. Pieces of flat sheet metal, typically referred to as blanks, is fed into a sheet metal stamping press that uses a tool and die surface to form the metal into a new shape.

Die Casting

As you know, die casting is a metal manufacturing process in which molten metal is forced under high pressure into mold tooling cavities. And easily to obtain the desired metal shape, nowadays, it is a widely used in automotive, lighting, industrial, and households.

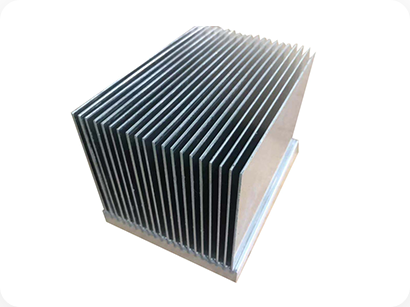

Extruded Heat Sink

Extrusion profile is the one commonly used process in different industrial areas by simple production and reasonable cost characteristic. It’s the first choice for heat sink design. After the cutting process, we can finish parts by CNC milling process, then do surface treatment base on customer request.

Extruded heat sinks are widely used in Military, Medical, Auto, Solar, Wind Power, New Energy, Fiber laser, Electric, and Telecommunication industries by simple production and good performance of heat dissipation. Everlucky focuses on thermal solution technology for 10 plus years, We have an innovative R&D team to provide thermal solution design for customers.

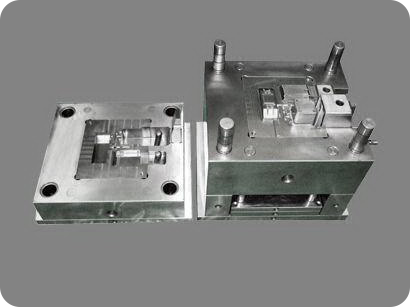

Injection Plastic Mold

An injection mold forms molten plastic into a specific shape for various uses. The mold is designed by an engineer or industrial designer then the specifications are given to a tool or mold maker to implement. Plastic injection molds are typically made from steel, or aluminum precision machined to conform to the exact product design specification. Injected molding can be used to create a wide variety of product sizes and applications from an automobile body to small components used in a vast number of industries

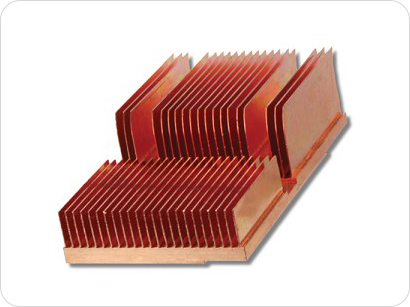

Skiving Heat Sink

Skiving is a manufacturing process where thermal solutions are formed by shaving one solid block of copper or aluminum into a finned heatsink. This method eliminates the resistance layer that is present with the solder layer in stacked fin heatsinks since skived fins are built from a single piece of metal. Skived fin heatsinks also require minimal tooling charges, which makes it a cost-effective solution.

Epoxy Bonding Fin

Bonded fin heat sink, also called bonded heat sink, is a heat sink assembly process that uses a high thermal conductivity bonding material to combine the heat sink base plate with the fins. This process is currently very mature and has been widely used. The application field includes heat dissipation of military equipment with strict requirements

Friction Stir Welding

Friction stir welding (FSW) is a solid-state joining process that uses a non-consumable tool to join two facing workpieces without melting the workpiece material. Heat is generated by friction between the rotating tool and the workpiece material, which leads to a softened region near the FSW tool. While the tool is traversed along the joint line, it mechanically intermixes the two pieces of metal, and forges the hot and softened metal by the mechanical pressure, which is applied by the tool.

Brazing & Soldering

Brazing can be done in many different ways. Two main styles are localised heating, where just the joint area is heated, and diffuse heating, where the entire object is heated.

During the process of brazing, the joining metal is melted and filled into the joint of the two parent metals by capillary action – that is the ability for liquids to flow in narrow spaces, without the help of gravity. The liquid metal is protected from oxidation during its liquid stage by a flux. The liquid metal is then cooled to join the pieces together.

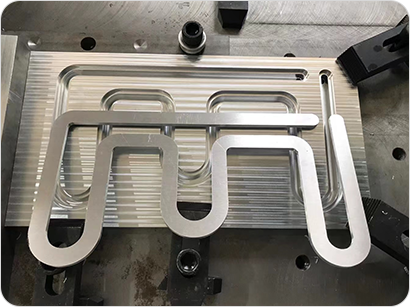

WEDM Process

In modern CNC machining, there is a special manufacturing process – wire EDM, which is different from turning and milling operation, its cutting tool does not need to touch the material when shaping the metal. How does wire EDM work? In this article, we’ll explore the wire electrical discharge machining process from multiple aspects.

EDM (Electrical discharge machining), also known as spark machining or spark eroding, is a manufacturing process of creating a desired part from the metal sheet by using electrical discharges (sparks).

What surface treatments can we do?

Anodized

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish, Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

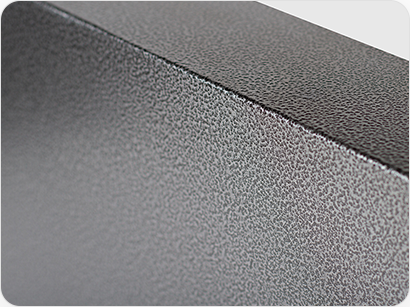

Powder Coating

Powder coating is a dry finishing process that has become extremely popular since its introduction in North America over in the 1960s. Representing over 15% of the total industrial finishing market, powder is used on a wide array of products. More and more companies specify powder coatings for a high-quality, durable finish, allowing for maximized production, improved efficiencies, and simplified environmental compliance. Used as functional (protective) and decorative finishes, powder coatings are available in an almost limitless range of colors and textures, and technological advancements have resulted in excellent performance properties.a

Painting

Steel paint Finishing is just one of the high-quality services we deliver at Lycett Fabrications, and this finish often goes hand-in-hand with fabrication, welding and material processing. As an organisation, you may take steel paint finishing for granted but there are many reasons why it is favoured for applications of all shapes, sizes and specifications.

Here we take a closer look at just five of the key benefits associated with steel paint finishing so you can discover a finish that is of the highest standard.

Polishing

Metal polishing is a finishing method that uses an abrasive material to smooth surfaces. When polished, the surfaces of metallic objects are freed of defects and become more reflective and shiny, enhancing their appearance. Metal polishing can be complemented by buffing, a less harsh method that results in a brighter finish.

Aside from its cosmetic value, metal polishing also serves a practical purpose. Beneath the surface, it removes oxidation from and prevents further corrosion of metal, significantly prolonging its working life.

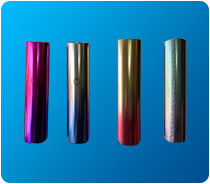

Electroplating

Electroplating technology has a very real effect on the products we see and use everyday. Engineers design products with this process in mind, factoring in how plating will strengthen and improve parts that are manufactured much less expensively in plastic or crude metal. Have you ever wondered what electroplating involves? Read on.

Electroplating is a type of metal finishing that applies the surface of a part or object with a layer of metal via electrical current. This process is also known as electrodeposition. This object or component, called a substrate, is connected to a negatively charged electrode. This is the cathode of the circuit.

Grinding

Surface grinding is used to produce a smooth finish on flat surfaces. It is a widely used abrasive machining process in which a spinning.

Brushing

Brushed or dull polished metal is metal with a unidirectional satin finish. It is produced by polishing the metal with a 120–180 grit belt or wheel then softening.

Screenprinting

Silkscreen is very popular on t-shirts and other fabrics, we can do it on metal parts for our customers.

Laser marking

Laser marking Everlucky provides the laser marking based on customer’s request, and we have multiple laser machining to meet the demand of customer.