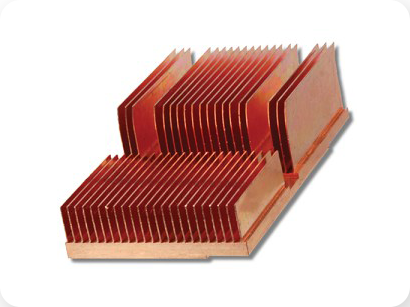

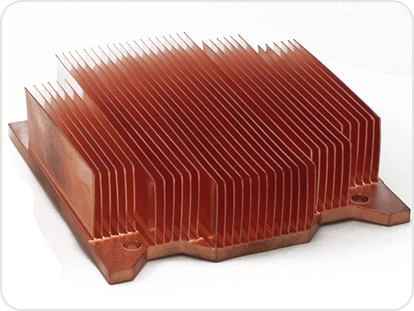

Skiving Heat Sink

Materials for skiving process are Aluminum and Copper.

Skived Fin Heat Sinks

Skiving is a manufacturing process where thermal solutions are formed by shaving one solid block of copper or aluminum into a finned heatsink. This method eliminates the resistance layer that is present with the solder layer in stacked fin heatsinks since skived fins are built from a single piece of metal. Skived fin heatsinks also require minimal tooling charges, which makes it a cost-effective solution. Skived heatsinks can also be customized with embedded heatpipes to add a performance boost if needed

Advantages

01

Comparing to the extrusion heat sink, skiving fin heat sink nearly has no requirement of density between fins.

02

Multiple raw material choice in market and we easily get standard aluminum and copper plate to meet our production demand. Especially we can develop a simple and cheaper cost extrusion tool as well.

03

Comparing to the soldering or inserting process, skiving parts are less heat resistance by there no any other mediums between base and fins.

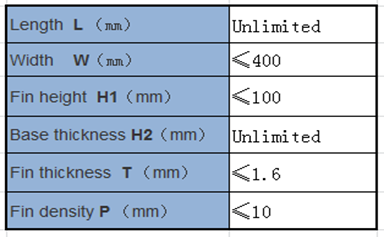

Design Parameter Reference